Being able to take control of nitrogen supplies as opposed to having to rely on a third party, can reduce operational costs significantly.

These integrated nitrogen generation systems from Parker Industrial Division use pre-treated air from a standard industrial compressor which is essentially “sieved” so that oxygen and other trace gases are removed while nitrogen is allowed to pass through to the application as the product gas. Air separation is not a new idea, but the radical Pressure Swing Adsorption (PSA) design and control systems employed on the Parker nitrogen generator ranges have maximised gas output and reduced compressed air consumption to achieve even higher levels of efficiency than before.

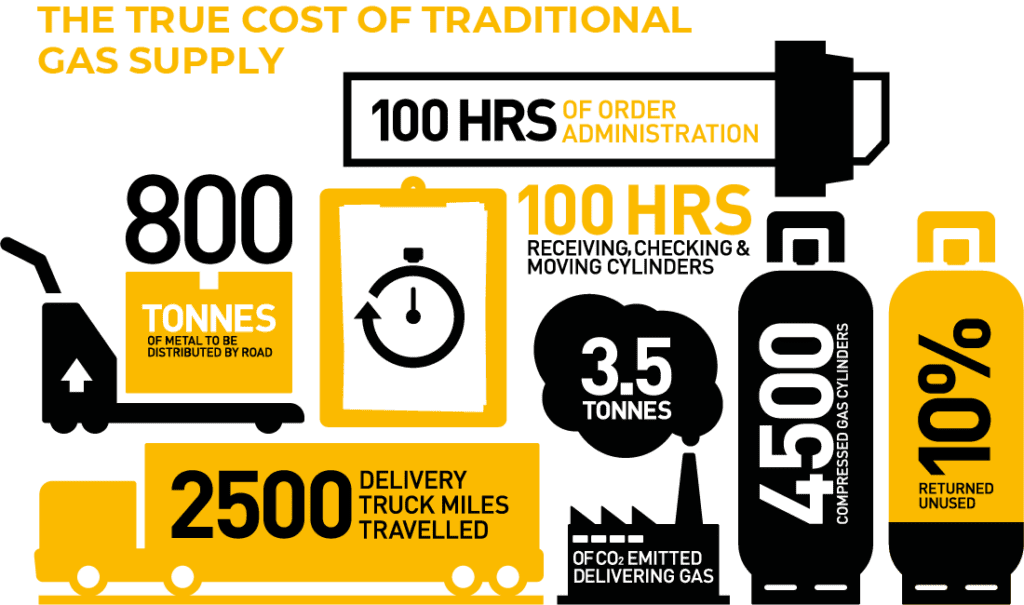

A nitrogen generation system can reduce costs by up to 90% when compared to traditional methods of supply. If a company using liquid nitrogen were to convert to gas generation technology, the new system could be expected to pay for itself in typically less than two years. For a company using cylinders, the payback period could be even earlier, less than 12 months in many cases.

The new systems can also make the workplace considerably safer for employees, eliminating the safety risks of storage, handling and changing heavy, high pressure cylinders.

- Controlled Atmosphere (CA) Storage

- Modified Atmosphere Packaging (MAP)

- Wine & Beverage

- Food Storage

- Laboratory Use

- Compressed Air Treatment

- Oil and Gas

- Laser Cutting

Here are Three Reasons Why Nitrogen is the Inert Gas of Choice for Winemakers.

Generating your own nitrogen eliminates the hassles of supplied cylinders, dewars or bulk nitrogen. A nitrogen generator dispels any concerns about lines icing up, running low, or running out of nitrogen. Costly downtime, tank rental fees, Haz-Mat fees, delivery fuel surcharges, price increases, evaporation concerns, and multi-year lease agreements will all be eliminated. Producing your own nitrogen eliminates reliance on outside vendors, allowing your business to be more self-sufficient.

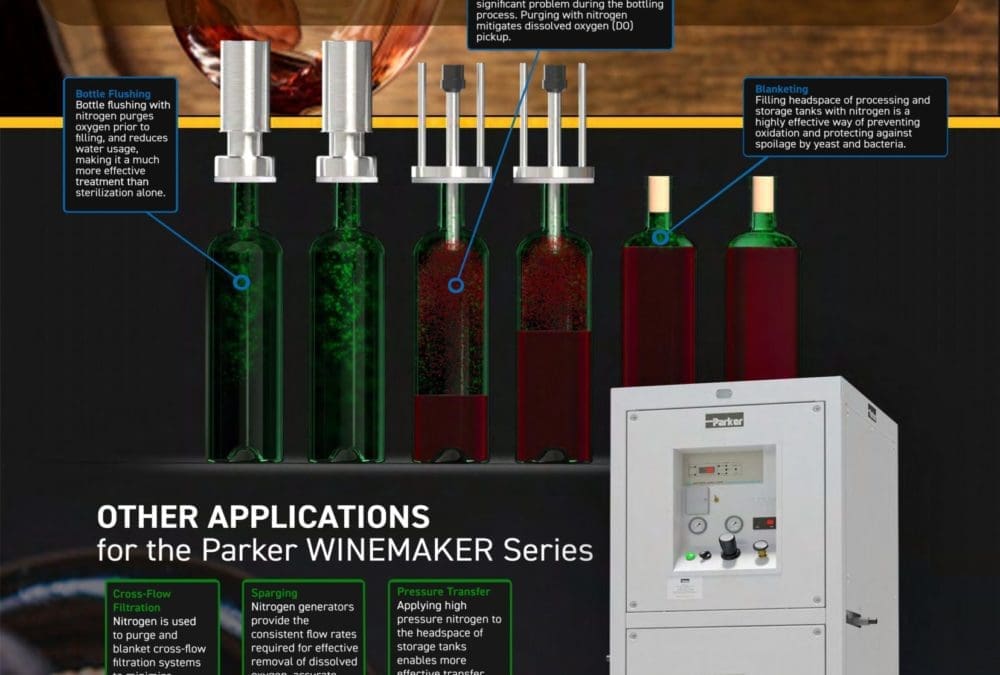

From fermentation to bottling, nitrogen has an important role to play in modern winemaking. Nitrogen is used for purging or blanketing tanks, racking barrels, flushing bottles, and at any point where the wine comes in contact with air.

- Nitrogen can be generated on-site from your air compressor.

- Nitrogen is the most abundant gas in the earth’s atmosphere, making it far less expensive than argon.

- Unlike carbon dioxide, nitrogen does not add the risk of adding carbonization to your wine.

- Long-term price stability.

- No contract administration with bulk gas suppliers.

- Reliable, long-term supply of nitrogen in-house.

- No supply shortage, especially when production increases.

- More cost-effective and reliable compared to tank delivery.

A cost-effective alternative

On-site generation provides a reliable source of nitrogen at the lowest total cost available. Generating your own nitrogen eliminates the hassles of supplied cylinders, dewars or bulk nitrogen. A nitrogen generator, such as the Parker WineMaker series, produces 98 to 99.9 percent pure, dry nitrogen on-demand and dispels any concerns about lines icing up, running low, or running out of nitrogen.

Features include:

- Complete package with pre-filtration, and receiving tank.

- Digital Oxygen analyser and Digital gas flow meter.

- Plugs into 110 volt outlet.

- Portable and expandable.

- Lease to own options available.

- Services wineries producing from 5,000 to 1 million+ cases.

- Ensures minimal DO pick up.

Easy installation and operation

Installation is simple: pipe in compressed air and pipe out nitrogen. Just connect a standard compressed air line to the inlet of the generator, connect the outlet to your nitrogen line and the unit is ready for trouble-free operation. The system is designed to operate 24 hours/day, 7 days/week. There is no complicated operating procedure or labour-intensive monitoring involved. Simply select the purity your process requires and set the flow and within minutes, high purity, dry nitrogen is available. Once the nitrogen generator is installed, the system requires very little maintenance.

From Auckland to Wanaka, Parker provides solutions for every variety of winemaking, and for the key stages in the production, storage and bottling process. We partner with food and beverage customers around the world, sharing expertise and know-how to develop new, better and more productive ways of making wine.